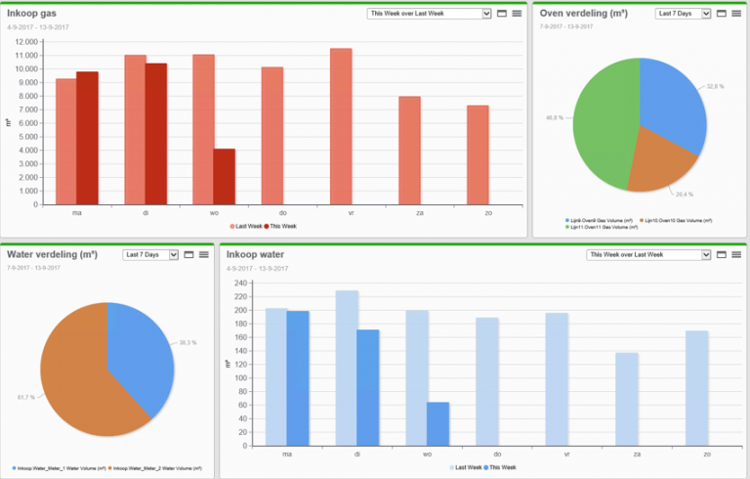

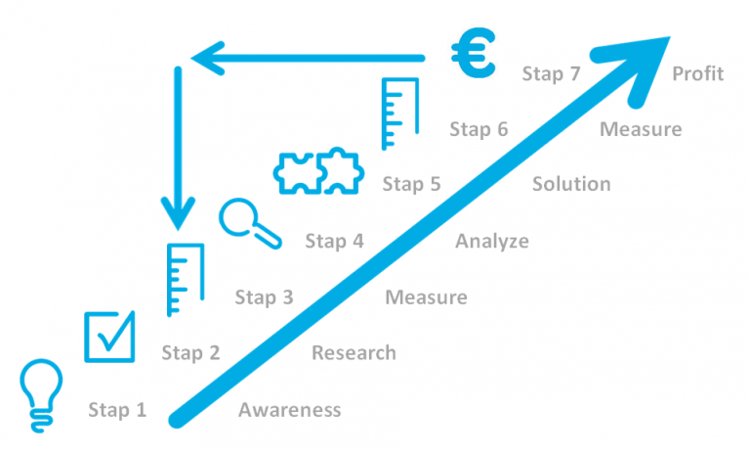

In the industrial sector, where energy-intensive processes are the norm, electrification plays a crucial role in the transition to sustainability. Batenburg Techniek automates industrial processes and supports customers in electrification with energy management solutions. We assist customers in automating heating systems, guiding them in the smart reuse, storage, and generation of heat at strategic moments. Additionally, we provide insights into energy consumption per process and batch, enabling us to optimize production planning based on sustainable and cost-effective energy.

The next step

in sustainable business